Challenger Rotary Series:

Mastery in Compact Filling Solutions

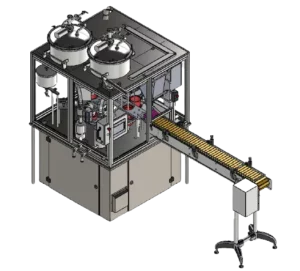

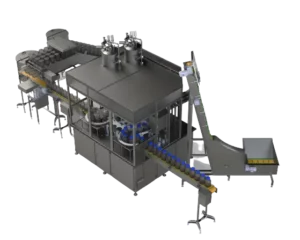

Introducing the Challenger Rotary series – our flagship range of automated filling and packaging machines designed for spaces where precision meets efficiency. From the efficient 333 model to the heavy-duty 888 version, this series caters to diverse production scales, ensuring you find the perfect match for your needs.

Every machine in the Challenger Rotary series is engineered for spaces where efficiency is vital. Their unique designs allow for top-notch production in areas both expansive and compact. Whether you’re working with a snug 1 m² or have a vast industrial space at your disposal, there’s a Challenger Rotary machine tailored for you.

Experience the future of filling solutions with the Challenger Rotary series – where compact design meets unmatched efficiency.

TAILORED FOR MEDIUM-SCALE OPERATIONS, THE 333 IS A COST-EFFECTIVE CHOICE. WITH ITS ADEPTNESS AT FILLING PLASTIC CONTAINERS AND SECURING THEM WITH A ROBUST THERMAL WELD, IT TARGETS A PRODUCTION CAPACITY OF UP TO 1,500 PACKAGES PER HOUR.

A VERSATILE MIDDLE-GROUND BETWEEN THE 333 AND 888, THE 666 CATERS TO MEDIUM TO HIGH PRODUCTION DEMANDS. HANDLING BETWEEN 1,500 TO 2,500 UNITS PER HOUR, IT’S A CIRCULAR SYSTEM MARVEL. WHETHER IT’S LIQUIDS OR SEMI-LIQUIDS, THIS MACHINE FILLS A DIVERSE RANGE OF PLASTIC CONTAINERS IN MULTIPLE SIZES AND SHAPES. THE FIVE STAGES SEAMLESSLY BLEND INTO ONE ANOTHER: PULLING THE EMPTY CONTAINERS, PRECISE FILLING, PLACING THE COVERS, IMPECCABLE WELDING, AND THEN SMOOTHLY TRANSITIONING THE SEALED PACKAGES ONTO THE CONVEYOR.

FOR BUSINESSES AIMING FOR THE SUMMIT OF HIGH-VOLUME PRODUCTION, THE 888 STANDS UNMATCHED. THIS BEHEMOTH MANAGES OVER 3,000 UNITS PER HOUR, ENSURING EVERY STAGE OF THE PROCESS IS STREAMLINED TO PERFECTION.

Experience the future of filling solutions with the Challenger Rotary series – where compact design meets unmatched efficiency.

Enjoy Watching!!