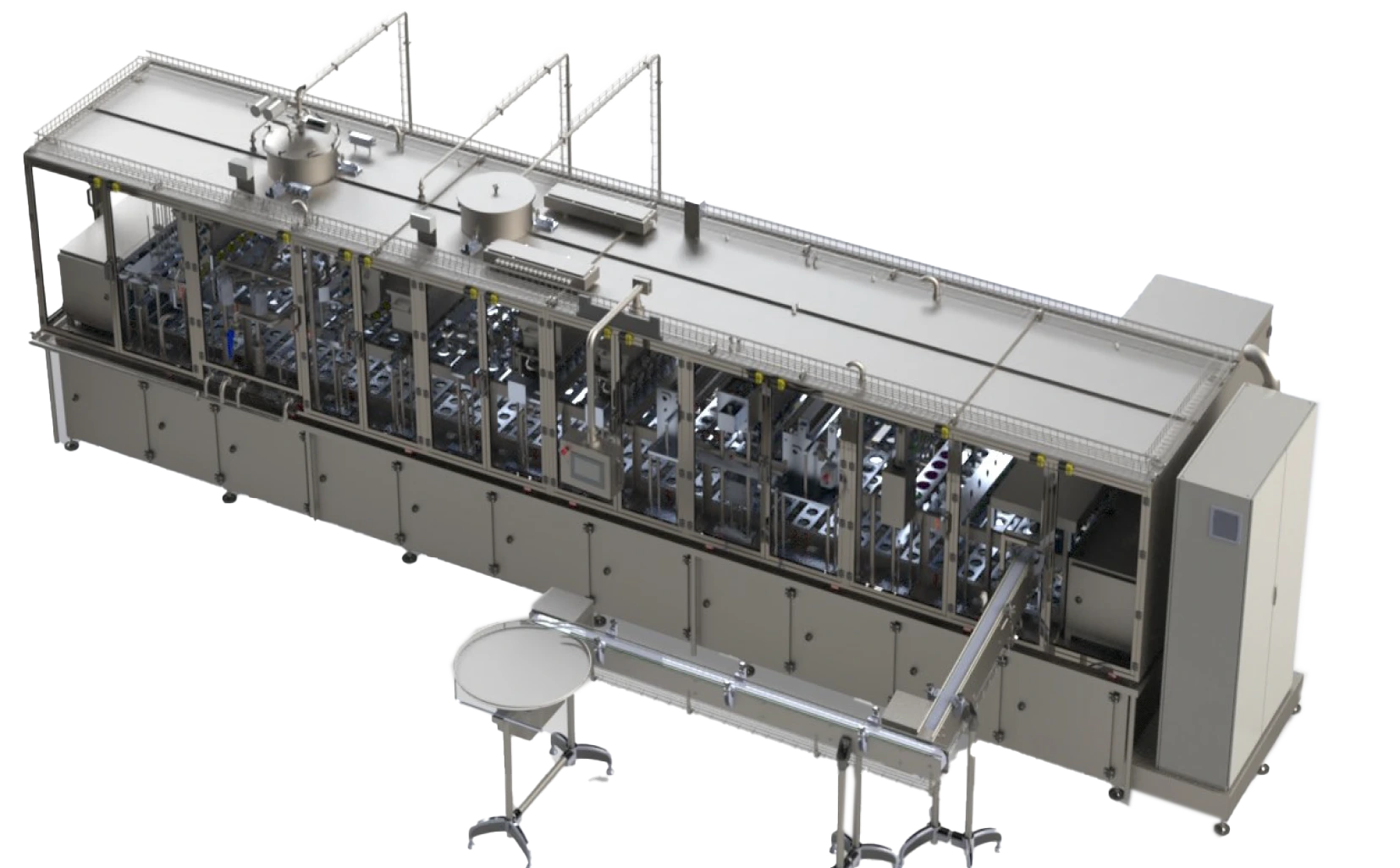

Challenger Linear A200 Series:

The Pinnacle of Automated Filling Technology

Introducing the Challenger A200 series, our flagship in heavy-duty filling and packaging. This state-of-the-art linear machine is tailored for a diverse range of liquid and paste products, from yogurt and water to hummus and molasses. It boasts an impressive capacity, accommodating fill volumes up to 1 Kg and handling as many as 25,000 cups every hour.

Designed with precision, every component of the A200 operates through consistent mechanical movements powered by its gearbox, seamlessly integrated with an electric motor. The result? Unmatched longevity, unparalleled work efficiency, effortless speed control, and the bonus of hassle-free maintenance.

The machine’s intuitive design comprises five distinct workstations, streamlining the entire process. Begin with a user-friendly touchscreen interface, which sets the production in motion. The sequence then follows:

01 Cup Feeding:

Seamless placement and arrangement of cups.

02 Volume Packing:

Accurate and consistent filling of the desired product.

03 Aluminum Covering:

Precise placement of protective aluminum covers.

04 Seal Affixation:

Ensuring the aluminum covers are securely sealed.

05 Conveyor Transition:

Directing the finished product to the conveyor belt for further processing.

Moreover, this series offers customization – adapt existing stages or introduce new ones based on specific project requirements.

Safety and efficiency are at the heart of the A200 series. Integrated electronic sensors constantly monitor the machine, detecting any shortages, temperature fluctuations, pressure discrepancies, or potential malfunctions. Any irregularity is promptly displayed on the touch screen, ensuring quick troubleshooting without unnecessary downtime.

Rounding off its stellar features, the machine includes a self-cleaning function for the filling unit, fully compatible with CIP (Clean-In-Place) systems.