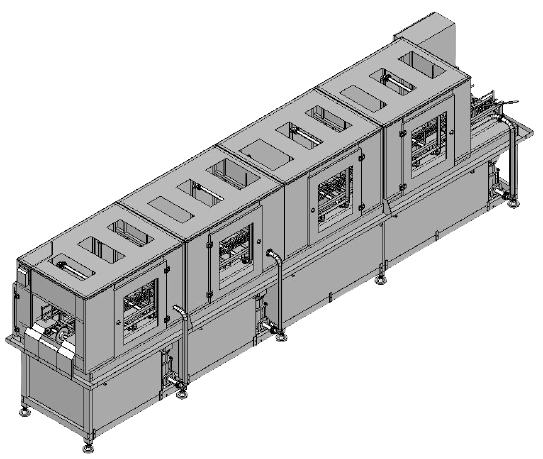

Box Washing machine:

The Pinnacle of Box Sterilization and Cleaning

Discover unparalleled cleanliness and hygiene with the Challenger 200B-3, our state-of-the-art box washing solution specifically crafted for the demanding dairy industry.

Elevate hygiene standards and ensure the safety of your dairy products with the Challenger 200B-3 box washing machine – where thoroughness meets efficiency.

This description focuses on the machine’s comprehensive washing and sterilization process, emphasizing its importance for the dairy industry.

01 Multi-Stage Washing Excellence

The 200B-3 doesn’t just wash – it rejuvenates. Utilizing a meticulously designed multi-stage cleaning process, it subjects boxes to a thorough cleansing using acid and soda. This not only ensures the removal of stubborn contaminants but also guarantees a deep sanitization.

02 Optimal Sterilization

After the intensive washing stages, boxes are treated with hot water, ensuring any lingering microorganisms are eliminated. This sterilization process guarantees that every box exiting the 200B-3 is not only clean but also safe for storing and transporting dairy products.

03 Vollautomatisches System

With automation at its core, the 200B-3 ensures consistency in every wash. It effectively handles multiple boxes, ensuring each one meets the rigorous cleanliness and hygiene standards set by the dairy industry.

04 Economic & Eco-Friendly

Designed keeping both economy and environment in mind, the 200B-3 ensures optimal water and chemical usage. This results in lower operational costs and a reduced environmental footprint.

05 Consistency & Reliability

Every box that goes through the 200B-3 comes out meeting the same high standard of cleanliness and sterility, ensuring consistency and building trust in your dairy products.